Featured products

Raspberry Pi 5 8GB Board

RP SC20211

Featuring a 64-bit quad-core Arm Cortex-A76 processor running at 2.4GHz, Raspberry Pi 5 delivers a 2-3x increase in CPU performance relative to Raspberry Pi 4! Raspberry Pi 5 also brings with it a huge list of great new features and improvements, making this the best Raspberry Pi yet!

2-3x CPU performance increase

The new 64-bit quad-core Arm Cortex-A76 processor at the heart of Raspberry Pi 5 runs at 2.4GHz with cryptography extensions, 512KB per-core L2 caches and a 2MB shared L3 cache. This new Broadcom BCM2712 SoC (System on Chip) provides a 2-3x increase in performance over the previous generation of Raspberry Pi!

Improved graphics performance with dual 4Kp60 display output

Raspberry Pi 5 delivers a substantial uplift in graphics performance from the 800MHz VideoCore VII GPU, connected to the BCM2712 via PCI Express. This allows Raspberry Pi 5 to offer full dual 4Kp60 display output via micro HDMI. These performance improvements provide a smooth desktop experience whilst browsing the internet and streaming videos.

Enhanced I/O capabilities including PCI-E!

For the first time, this is a full-size Raspberry Pi computer using silicon built in-house at Raspberry Pi. The RP1 "southbridge" provides the bulk of the I/O capabilities for Raspberry Pi 5, and delivers a step change in peripheral performance and functionality.Aggregate USB bandwidth is more than doubled, yielding faster transfer speeds to external UAS drives and other high-speed peripherals

Peak MicroSD card performance is doubled, through support for the SDR104 high-speed mode

Single-lane PCI Express 2.0 interface, providing support for high-bandwidth peripherals.

Power button (finally!)

Makers and enthusiasts have been asking for a dedicated onboard power button on the Raspberry Pi for as long as we can remember - and Raspberry Pi 5 finally delivers this much-requested convenience!

Real-time clock (RTC)

A real-time clock (RTC) is built into the board, allowing you to maintain time/date information even when you power off or aren't connected to the internet (when a backup battery is connected). A dedicated header on the board has been added to allow the use of a backup battery for the RTC. A lithium battery with a compatible header will be available on, or shortly after, the launch of Raspberry Pi 5.

Dedicated fan header

Raspberry Pi 5 includes a new dedicated fan header to the right of the familiar GPIO pin header, allowing you to connect and run a cooling fan without interfering with your GPIO-connected devices. Now you can add HATs and other hardware without workarounds to connect a fan.

Dedicated UART header

Another handy addition to Raspberry Pi 5 is the dedicated UART header. Now you can debug and control your Raspberry Pi 5 headlessly and without interfering with your GPIO pins. This dedicated UART header also allows debugging from boot, and is designed to be used with the Raspberry Pi Debug probe for quick, convenient debugging.

Plus other improvements and changesMounting holes for coolers/heatsinks (designed for the Raspberry Pi Active Cooler)

Composite video header

Memory indication markers for easy board RAM identification

Unique board ID number on the board and packaging

Relocated PoE header

Audio jack removed

Flush(ish) underside to GPIO pins

Metal supporting tabs to protect components on the underside

2-3x CPU performance increase

The new 64-bit quad-core Arm Cortex-A76 processor at the heart of Raspberry Pi 5 runs at 2.4GHz with cryptography extensions, 512KB per-core L2 caches and a 2MB shared L3 cache. This new Broadcom BCM2712 SoC (System on Chip) provides a 2-3x increase in performance over the previous generation of Raspberry Pi!

Improved graphics performance with dual 4Kp60 display output

Raspberry Pi 5 delivers a substantial uplift in graphics performance from the 800MHz VideoCore VII GPU, connected to the BCM2712 via PCI Express. This allows Raspberry Pi 5 to offer full dual 4Kp60 display output via micro HDMI. These performance improvements provide a smooth desktop experience whilst browsing the internet and streaming videos.

Enhanced I/O capabilities including PCI-E!

For the first time, this is a full-size Raspberry Pi computer using silicon built in-house at Raspberry Pi. The RP1 "southbridge" provides the bulk of the I/O capabilities for Raspberry Pi 5, and delivers a step change in peripheral performance and functionality.

Power button (finally!)

Makers and enthusiasts have been asking for a dedicated onboard power button on the Raspberry Pi for as long as we can remember - and Raspberry Pi 5 finally delivers this much-requested convenience!

Real-time clock (RTC)

A real-time clock (RTC) is built into the board, allowing you to maintain time/date information even when you power off or aren't connected to the internet (when a backup battery is connected). A dedicated header on the board has been added to allow the use of a backup battery for the RTC. A lithium battery with a compatible header will be available on, or shortly after, the launch of Raspberry Pi 5.

Dedicated fan header

Raspberry Pi 5 includes a new dedicated fan header to the right of the familiar GPIO pin header, allowing you to connect and run a cooling fan without interfering with your GPIO-connected devices. Now you can add HATs and other hardware without workarounds to connect a fan.

Dedicated UART header

Another handy addition to Raspberry Pi 5 is the dedicated UART header. Now you can debug and control your Raspberry Pi 5 headlessly and without interfering with your GPIO pins. This dedicated UART header also allows debugging from boot, and is designed to be used with the Raspberry Pi Debug probe for quick, convenient debugging.

Plus other improvements and changes

€90.95

Snapmaker A350T 3 in 1 3D Printer Bundle

SNAP A350T

Snapmaker 2.0 A350T Modular 3-in-1 3D Printer & Enclosure Bundle

The Snapmaker 2.0 A350T 3-in-1 modular system is powerful and customisable, featuring everything you need to start your maker journey. 3D Printing, CNC and laser modules make the Snapmaker A350T a perfect machine for every maker.

This enclosure bundle means you get the added benefits of reduced fumes and even more reduced noise! With add-ons such as the air purifier you can ensure you A350T is safe for any environment.

The Snapmaker 2.0 A350T 3-in-1 modular system is powerful and customisable, featuring everything you need to start your maker journey. 3D Printing, CNC and laser modules make the Snapmaker A350T a perfect machine for every maker.

This enclosure bundle means you get the added benefits of reduced fumes and even more reduced noise! With add-ons such as the air purifier you can ensure you A350T is safe for any environment.

€2750.00

€1999.95

Casio FX-83GT CW Scientific Calculator Range

CASIO FX83GTCW-RANGE

The Casio fx-83GT CW is the new upgraded version of the Casio fx-83GT X (the UK’s best-selling scientific calculator), containing additional features, to include a high definition display and improved menu navigation. Allowed in every Irish & UK exam where a calculator can be used. Recommended and approved for Junior and Leaving Cert , GCSE, National and Higher.

This scientific calculator has arithmetic and scientific calculations, statistical calculations including quartiles, table of values for up to two functions, and calculation of equivalent ratios. There is a Maths Box with probability simulation, number line and unit circle display.

The new interface features scrolling menus, all mathematical functions available in a single catalogue key and number formats available in a format key. The new display has a new font and 4-tone input for extra clarity.

Suitable for all levels up to Leaving Cert and for basic professional work.

This scientific calculator has arithmetic and scientific calculations, statistical calculations including quartiles, table of values for up to two functions, and calculation of equivalent ratios. There is a Maths Box with probability simulation, number line and unit circle display.

The new interface features scrolling menus, all mathematical functions available in a single catalogue key and number formats available in a format key. The new display has a new font and 4-tone input for extra clarity.

Suitable for all levels up to Leaving Cert and for basic professional work.

€17.95

Micro:bit V2 Club Class Set of 10

MIC 495

Perfect for sharing the micro:bit with friends, the micro:bit club is a 10 pack containing all the pieces needed to enjoy micro:bit in STEM groups, coding clubs, school classes, scouts, guides and cubs or any other social gathering (contains 10 BBC micro:bits V2, 10x USB cables, 10 x battery holders ; 20x AAA batteries).

The micro:bit is a pocket-sized computer that you can code, customise and control to bring your digital ideas, games and apps to life. Measuring 4cm by 5cm, and designed to be fun and easy to use, users can create anything from games and animations to scrolling stories at school, at home and on the go - all you need is imagination and creativity.

The micro:bit is completely programmable. That means each of its LEDs can be individually programmed as can its buttons, inputs and outputs, accelerometer, magnetometer and Bluetooth Smart Technology. The micro:bit has a website full of coding languages, lesson plans, tutorials, and fun ideas to help you get creative

The micro:bit is a pocket-sized computer that you can code, customise and control to bring your digital ideas, games and apps to life. Measuring 4cm by 5cm, and designed to be fun and easy to use, users can create anything from games and animations to scrolling stories at school, at home and on the go - all you need is imagination and creativity.

The micro:bit is completely programmable. That means each of its LEDs can be individually programmed as can its buttons, inputs and outputs, accelerometer, magnetometer and Bluetooth Smart Technology. The micro:bit has a website full of coding languages, lesson plans, tutorials, and fun ideas to help you get creative

€209.00

Bestsellers

Wooden Box with Compass, Tape & Elastika Set Squares

KIT TG BOX E

Deluxe Technical Graphics in our own brand strong wooden box which includes:

Elastika Unbreakable Set Squares 45° and 60°

SG German made Quickset Compass

Columbus H & 2H Pencils

Quality 12 mm Drafting Masking Tape

Protractor 10cm

Vinyl Eraser

Metal Sharpener

To discuss a Bespoke Kit for your School, please contact SG Education on 071 91 53810 or email sales@sgeducation.ie

To discuss a Bespoke Kit for your School, please contact SG Education on 071 91 53810 or email sales@sgeducation.ie

€23.00

Compass Leads HB Pack of 10

KCOL10

10 Compass leads HB in a plastic tub

Set of compass leads with a diameter of 2 mm and length of 19 mm, oblique. Leads are suitable for both school and technical compasses. They are produced in medium hardness degree.

Set of compass leads with a diameter of 2 mm and length of 19 mm, oblique. Leads are suitable for both school and technical compasses. They are produced in medium hardness degree.

€1.40

Tesa Drafting Masking Tape Range

TESA MASKING TAPE-RANGE

The Tesa Drafting Masking Tape Range is a reliable and precise tool for professional drafting and design work. With its low-tack adhesive, it adheres securely to paper and other surfaces without causing damage or leaving residue.

The tape's easy-tear feature allows for quick and accurate application, making it perfect for creating crisp and clean edges. Available in different widths, the Tesa Drafting Masking Tape Range offers versatility and precision for architects, artists, and designers.

The tape's easy-tear feature allows for quick and accurate application, making it perfect for creating crisp and clean edges. Available in different widths, the Tesa Drafting Masking Tape Range offers versatility and precision for architects, artists, and designers.

€1.21

SG Micro:bit V2 Project Kit

SG CSKIT2

Build up to six projects straight out of the box with this great value SG Education Project Kit for the BBC micro:bit.

The perfect way to get started with programming and hardware interaction.

No soldering required,

all parts are included to build 6 projects.

Small prototype breadboard and

2 x AAA Batteries are included.

Included in the kit are:

BBC Micro:Bit

Mini Breadboard

Shielded Croc Leads

USB to mini USB cable

Red-Green-Amber LED's

Clips

Battery cage

AAA batteries included

The projects that can be built are:

Dice

Theremin

Miniature Steady Hand Game

Fruit Keyboard

Traffic Light

Included in the kit are:

BBC Micro:Bit

Mini Breadboard

Shielded Croc Leads

USB to mini USB cable

Red-Green-Amber LED's

Clips

Battery cage

AAA batteries included

The projects that can be built are:

Dice

Theremin

Miniature Steady Hand Game

Fruit Keyboard

Traffic Light

€24.94

Faber Castell Columbus Pencils Pack of 12 Range

COLUMBUS 12 PACK-RANGE

Columbus Pencils in Packs of 12

The Columbus pencil was first manufactured here in Ireland in the 1950s. Since then this distinctive pencil has gone on to become Ireland's favourite. It is made from the highest quality Californian Cedar wood and German leads.

The range has the right pencils for every task. 6B to B are for artwork, the soft leads are perfect for sketching and shading. HB through 5H are specially made for writing, drafting and fine lines.

The Columbus pencil was first manufactured here in Ireland in the 1950s. Since then this distinctive pencil has gone on to become Ireland's favourite. It is made from the highest quality Californian Cedar wood and German leads.

The range has the right pencils for every task. 6B to B are for artwork, the soft leads are perfect for sketching and shading. HB through 5H are specially made for writing, drafting and fine lines.

€5.10

SG A2 Hardwood T-Square

SG TSQA2

Strong T-Square made from hardwood A2. 60cm in length.

Selected by SG as a best quality recommendation for Technical Graphics and DCG in schools.

Selected by SG as a best quality recommendation for Technical Graphics and DCG in schools.

€8.95

Cartridge Paper 120g Range (500 Sheets)

CARTRIDGE PAPER 120G RANGE (500 SHEETS)

The 120g cartridge paper is a medium-weight paper that is suitable for a wide range of applications. It is thick enough to resist tearing and creasing, yet still lightweight enough to be easily handled and stored.

This weight of cartridge paper is commonly used for sketches, preliminary drawings, and for ink and pencil work.

Comes in a pack of 500 sheets

This weight of cartridge paper is commonly used for sketches, preliminary drawings, and for ink and pencil work.

Comes in a pack of 500 sheets

€29.50

Casio FX-83GT CW Scientific Calculator Range

CASIO FX83GTCW-RANGE

The Casio fx-83GT CW is the new upgraded version of the Casio fx-83GT X (the UK’s best-selling scientific calculator), containing additional features, to include a high definition display and improved menu navigation. Allowed in every Irish & UK exam where a calculator can be used. Recommended and approved for Junior and Leaving Cert , GCSE, National and Higher.

This scientific calculator has arithmetic and scientific calculations, statistical calculations including quartiles, table of values for up to two functions, and calculation of equivalent ratios. There is a Maths Box with probability simulation, number line and unit circle display.

The new interface features scrolling menus, all mathematical functions available in a single catalogue key and number formats available in a format key. The new display has a new font and 4-tone input for extra clarity.

Suitable for all levels up to Leaving Cert and for basic professional work.

This scientific calculator has arithmetic and scientific calculations, statistical calculations including quartiles, table of values for up to two functions, and calculation of equivalent ratios. There is a Maths Box with probability simulation, number line and unit circle display.

The new interface features scrolling menus, all mathematical functions available in a single catalogue key and number formats available in a format key. The new display has a new font and 4-tone input for extra clarity.

Suitable for all levels up to Leaving Cert and for basic professional work.

€17.95

Maths Tables ; Formulae & Tables Log Book

MATH TABLES

Maths Tables

New edition of the Maths Formulae and Tables Log Book

Log Tables approved for use in the state examinations.

€3.95

Masking Tape Economy Range

MT ECON-RANGE

Masking Tape - Economy Range

General Purpose masking tape.

This tape will stick strongly, high tack

General Purpose masking tape.

This tape will stick strongly, high tack

€0.85

Just Arrived!

Makey Makey GO

MAK 100978

Makey Makey GO empowers modern-day creators, visionaries, and innovators with the freedom to invent wherever inspiration strikes. With Makey Makey GO, innovation is at your fingertips - literally. Simply attach an alligator clip, and watch ordinary objects transform into Internet touchpads, ready to revolutionize the world.

Compact enough to hang on your keychain or slip into your pocket, Makey Makey GO is poised to ignite even more STEM projects than its predecessor, the acclaimed Makey Makey, which earned a spot on Consumer Reports' list of "Best Tech Toys of 2014.

Turn everyday objects like bananas into touchpads!

Connect the world around you to your computer! Setup takes just seconds.

Just plug, clip, and play! No programing knowledge needed. No software to install. Works with Mac and Windows.

1000s of possibilities! Make Cardboard Smart Swords, Slack Line Score Boards, and Animal Skype Phones.

Ages 8 to infinity.

Contents:1 USB Invention Stick

Case with magnet

1 white alligator clip (2.5 ft)

Keyring

Instruction guide

Compact enough to hang on your keychain or slip into your pocket, Makey Makey GO is poised to ignite even more STEM projects than its predecessor, the acclaimed Makey Makey, which earned a spot on Consumer Reports' list of "Best Tech Toys of 2014.

Contents:

€27.95

Crafter's Companion Stick and Spray Mounting Adhesive 250ml

CRC STK-SPR

Crafters Companion Stick and Spray Mounting Adhesive. Spray, Stamp, and Stick! Easy as pie. If you're searching for a lightweight adhesive spray that lets you reposition your stamps repeatedly, your quest ends here.

Crafters Companion's Stick and Spray Mounting Adhesive stands out from the crowd. Its fine mist allows you to apply adhesive to various materials, including unmounted stamps, enabling you to move and readjust them up to 30 times.

Acid and lignin free

Simply Spray, Stamp and Stick

Reposition up to 30 times after spraying

Use with any unmounted stamps

Crafters Companion's Stick and Spray Mounting Adhesive stands out from the crowd. Its fine mist allows you to apply adhesive to various materials, including unmounted stamps, enabling you to move and readjust them up to 30 times.

€9.99

SG Raspberry Pi5 4GB Starter Kit

RP KIT PI5 4GB

Discover our comprehensive Raspberry Pi 5 starter kit, offering exceptional value. Equipped with the latest generation Raspberry Pi 5 board and all essential accessories, it provides everything you need to kickstart your projects swiftly and seamlessly.

Starter Kit Contents:Raspberry Pi 5 4GB - Featuring a 64-bit quad-core Arm Cortex-A76 processor running at 2.4GHz, Raspberry Pi 5 delivers a 2-3x increase in CPU performance relative to Raspberry Pi 4! Raspberry Pi 5 also brings with it a huge list of great new features and improvements, making this the best Raspberry Pi yet.

Raspberry Pi 27W USB-C Power Supply - The official recommended power supply for the Raspberry Pi 5. This power supply will provide 5V/5A and enable you to use the board to its full potential and performance, ensuring a full possible current supply to USB devices.

Raspberry Pi 5 Case - The official case for the Raspberry Pi 5, and a refinement of the previous case design, with a number of improvements and thermal features to accommodate the footprint and peak power consumption of Raspberry Pi 5. Important - remove your SD card before fitting or removing your Raspberry Pi from the case.

SanDisk 32GB MicroSD card - An authentic 32GB Class 10 SanDisk MicroSD card pre-loaded with the latest Raspberry Pi OS

Raspberry Pi MicroSD Adapter - Convert your Micro SD card into a full-sized SD

Micro-HDMI to HDMI cable - A high-speed Micro-HDMI to HDMI cable for connecting your Raspberry Pi 5 to a display, tested for compatibility with the Pi 5.

Starter Kit Contents:

€108.95

SG Raspberry Pi5 8GB Starter Kit

RP KIT PI5 8GB

Discover our comprehensive Raspberry Pi 5 starter kit, offering exceptional value. Equipped with the latest generation Raspberry Pi 5 board and all essential accessories, it provides everything you need to kickstart your projects swiftly and seamlessly.

Starter Kit Contents:Raspberry Pi 5 8GB - Featuring a 64-bit quad-core Arm Cortex-A76 processor running at 2.4GHz, Raspberry Pi 5 delivers a 2-3x increase in CPU performance relative to Raspberry Pi 4! Raspberry Pi 5 also brings with it a huge list of great new features and improvements, making this the best Raspberry Pi yet.

Raspberry Pi 27W USB-C Power Supply - The official recommended power supply for the Raspberry Pi 5. This power supply will provide 5V/5A and enable you to use the board to its full potential and performance, ensuring a full possible current supply to USB devices.

Raspberry Pi 5 Case - The official case for the Raspberry Pi 5, and a refinement of the previous case design, with a number of improvements and thermal features to accommodate the footprint and peak power consumption of Raspberry Pi 5. Important - remove your SD card before fitting or removing your Raspberry Pi from the case.

SanDisk 32GB MicroSD card - An authentic 32GB Class 10 SanDisk MicroSD card pre-loaded with the latest Raspberry Pi OS

Raspberry Pi MicroSD Adapter - Convert your Micro SD card into a full-sized SD

Micro-HDMI to HDMI cable - A high-speed Micro-HDMI to HDMI cable for connecting your Raspberry Pi 5 to a display, tested for compatibility with the Pi 5.

Starter Kit Contents:

€131.95

WellBee 1 Year Licence Range

WELLBEE RANGE

Wellbee is a digital tool to help/assist people with cognitive difficulties who need support in order to have clarity in their daily life. By using Wellbee people with cognitive and executive function disabilities have the opportunity to be more self-sufficient and independent.

Wellbee is tailored to empower individuals with disabilities, who may struggle with daily tasks such as organisation, learning and remembering important information, or completing complex activities. Based on a model of having a “planner” and a “user”, Wellbee aids and encourages an independent style of learning and thriving for those who alternatively may not be able to do so.

Wellbee works on a user's phone (via the Wellbee iOS / Android app) and through their browser on any other device (laptop, desktop, Windows/Mac, Chromebook, iPad etc.)

Wellbee is tailored to empower individuals with disabilities, who may struggle with daily tasks such as organisation, learning and remembering important information, or completing complex activities. Based on a model of having a “planner” and a “user”, Wellbee aids and encourages an independent style of learning and thriving for those who alternatively may not be able to do so.

Wellbee works on a user's phone (via the Wellbee iOS / Android app) and through their browser on any other device (laptop, desktop, Windows/Mac, Chromebook, iPad etc.)

€265.00

Pimoroni NVMe Base for Raspberry Pi 5

PIM 699

Add super-fast storage to your Raspberry Pi 5 allowing for lightning fast boots, NAS use, and snappy applications! NVMe Base is a PCIe extension board for Raspberry Pi 5. Simply populate it with an M-key NVMe SSD (2230 to 2280 sizes supported) and mount it under your Pi for a compact and fast storage solution - It even comes with rubber feet!

It's the perfect solution for turning your Raspberry Pi 5 into a file server, media centre, reverse proxy, etc. - really any task that benefits from large amounts of fast storage, especially with random high operations per second (IOPS) workloads. In short it's a game changer!

NVMe base follows the new "PIP" design guidelines provided by Raspberry Pi ensuring that it will be easy to use and be supported long term by updates to Raspberry Pi OS - though it is very early days and things are improving rapidly there!

Base KitNVMe Base PCB with M.2 Slot (M-Key)

'PCIe Pipe' Flat Flex Cable

4x Rubber feet

M2 bolt and 2x nuts for SSD mounting

4x 7mm M2.5 standoffs for base mounting

8x short M2.5 bolts for base mounting

4x long M2.5 bolts for 'pass-thru' mounting with a HAT

Compatible with:Raspberry Pi 5

SSD card for use is the Verbatim Vi3000 PCIe NVMe M.2 SSD 256GB

It's the perfect solution for turning your Raspberry Pi 5 into a file server, media centre, reverse proxy, etc. - really any task that benefits from large amounts of fast storage, especially with random high operations per second (IOPS) workloads. In short it's a game changer!

NVMe base follows the new "PIP" design guidelines provided by Raspberry Pi ensuring that it will be easy to use and be supported long term by updates to Raspberry Pi OS - though it is very early days and things are improving rapidly there!

Base Kit

Compatible with:

SSD card for use is the Verbatim Vi3000 PCIe NVMe M.2 SSD 256GB

€19.25

Pimoroni Display HAT Mini

PIM 589

A generous 2.0" (320 x 240) IPS LCD display for Raspberry Pi with lots of tasty baked in functionality.

Display HAT Mini features a bright 18-bit capable 320x240 pixel display with vibrant colours and formidable IPS viewing angles, connected via SPI. It's got four tactile buttons for interacting with your Pi with your digits and a RGB LED for notifications. Pimoroni have also squeezed in a QwST connector (Qwiic / STEMMA QT) and a Breakout Garden header so it's a doddle to connect up different kinds of breakouts.

It will work with any model of Pi with a 40 pin header, it goes with the Raspberry Pi Zero particularly well - Pimoroni have included a pair of standoffs so you can use to bolt HAT and Pi together to make a sturdy little unit. To accommodate the screen Display HAT Mini is a bit bigger than a standard mini HAT or pHAT - it's around 5mm taller than a Pi Zero (so a Mini HAT XL or a Mini HAT Pro, if you will).

Display HAT Mini lets you turn a Raspberry Pi into a convenient IoT control panel, a tiny photo frame, digital art display or gif-box, or a desktop display for news headlines, tweets, or other info from online APIs. This screen is a handy 3:2 ratio, useful for retro gaming purposes!

Features:2.0” 320x240 pixel IPS LCD screen, connected via SPI (~220 PPI, 65K colours)

4 x tactile buttons

RGB LED

Qw/ST (Qwiic/STEMMA QT) connector

Breakout Garden / I2C header

Pre-soldered socket header for attaching to Raspberry Pi

Compatible with all models of Raspberry Pi with a 40 pin header.

Fully assembled

No soldering required (as long as your Pi has header pins attached).

Dimensions: approx 65.5mm x 35mm x 9mm (W x H x D, includes header and display). With a Pi Zero attached with standoffs, the total depth is 17mm.

Screen usable area: 40.8mm x 30.6mm (L x W)

Pinout

Schematic

Dimensional drawing

Display HAT Mini Python library

ST7789 Python library

IncludesDisplay HAT Mini

2 x 10mm standoffs

Compatible with:Raspberry Pi 5

Raspberry Pi 4

Raspberry Pi Zero(but needs Male 40-pin 2x20 HAT Header for Pi Zero)

Display HAT Mini features a bright 18-bit capable 320x240 pixel display with vibrant colours and formidable IPS viewing angles, connected via SPI. It's got four tactile buttons for interacting with your Pi with your digits and a RGB LED for notifications. Pimoroni have also squeezed in a QwST connector (Qwiic / STEMMA QT) and a Breakout Garden header so it's a doddle to connect up different kinds of breakouts.

It will work with any model of Pi with a 40 pin header, it goes with the Raspberry Pi Zero particularly well - Pimoroni have included a pair of standoffs so you can use to bolt HAT and Pi together to make a sturdy little unit. To accommodate the screen Display HAT Mini is a bit bigger than a standard mini HAT or pHAT - it's around 5mm taller than a Pi Zero (so a Mini HAT XL or a Mini HAT Pro, if you will).

Display HAT Mini lets you turn a Raspberry Pi into a convenient IoT control panel, a tiny photo frame, digital art display or gif-box, or a desktop display for news headlines, tweets, or other info from online APIs. This screen is a handy 3:2 ratio, useful for retro gaming purposes!

Features:

Includes

Compatible with:

€26.95

Pimoroni GFX HAT LCD Display for Raspberry Pi

PIM 400

A 128x64 pixel, 2.15" LCD display with snazzy six-zone RGB backlight and six capacitive touch buttons. GFX HAT makes an ideal display and interface for your headless Pi projects.

GFX HAT riffs off the previous Display-O-Tron HAT (now discontinued), but gives you the flexibility of individual pixels, letting you display more complex graphics and real typefaces, while retaining the handy capacitive touch buttons for input/navigation.

Features:128x64 pixel, 2.15" LCD display

Integrated diffuser/reflector assembly

Six-zone RGB LED backlight

SN3218 LED driver chip (I2C address 0x54)

Six capacitive touch buttons with white LEDs

Microchip CAP1166 capacitive touch/LED driver chip ((I2C address 0x2c)

Compatible with all 40-pin header Raspberry Pi models

Python library

Comes fully assembled

Compatible with:Raspberry Pi 5

Raspberry Pi 4

GFX HAT riffs off the previous Display-O-Tron HAT (now discontinued), but gives you the flexibility of individual pixels, letting you display more complex graphics and real typefaces, while retaining the handy capacitive touch buttons for input/navigation.

Features:

Compatible with:

€23.50

Pimoroni Pibow Coupe 4 Ninja (Case for Raspberry Pi 4)

PIM 463

The slim, hackable, and attractive case for the Raspberry Pi 4. Crafted out of five unique layers including a transparent top and base that leave your beautiful Raspberry Pi 4 visible inside. Each layer is laser-cut from high-quality, cast acrylic and once stacked they securely contain a Raspberry Pi 4 while leaving the primary ports, including the camera port, display port, and GPIO accessible.

Weighing just over 50 grams, the case is lightweight and ideal for mounting to any surface. No tools are required for assembly or disassembly. The dimensions are: 99x66x15mm (WxLxH, not including bolt heads and nuts).

FeaturesCompatible with Raspberry Pi 4 only

Cutout in lid for 40x30mm heatsink or Fan SHIM

Super-slimline profile

Fully HAT-compatible

Works great with standoffs!

Protects your beloved Pi!

Clear top and base (Ninja and Red) leave Raspberry Pi 4 visible

GPIO cut-out

Handy laser-etched port labels

Leaves all ports accessible

Made from lightweight, high-quality, cast acrylic

Great for hacking and tinkering!

Compatible with:Raspberry Pi 4

Weighing just over 50 grams, the case is lightweight and ideal for mounting to any surface. No tools are required for assembly or disassembly. The dimensions are: 99x66x15mm (WxLxH, not including bolt heads and nuts).

Features

Compatible with:

€14.00

Pimoroni Enviro for Raspberry Pi

PIM 486

Keep track of your surroundings using Enviro for Raspberry Pi! Equipped with a variety of advanced environmental sensors, these boards feature a beautiful full-color LCD screen to showcase your data. They offer an ideal introduction to citizen science and environmental monitoring!

Enviro is designed for indoor monitoring, letting you measure temperature, pressure, humidity, light, and noise level. It's great for keeping tabs on what's going on in rooms in your house, office, or elsewhere. Push the data to server and you can view the data remotely from anywhere.

BME280 temperature, pressure, humidity sensor (datasheet)

LTR-559 light and proximity sensor (datasheet)

MEMS microphone (datasheet)

0.96" colour LCD (160x80)

Pimoroni breakout-compatible pin header

pHAT-format board

Fully-assembled

Compatible with all 40-pin header Raspberry Pi models

Python library

Dimensions: 65x30x8.5mm

Compatible with:Raspberry Pi 5

Raspberry Pi 4

Raspberry Pi Zero (but needs Male 40-pin 2x20 HAT Header for Pi Zero)

Enviro is designed for indoor monitoring, letting you measure temperature, pressure, humidity, light, and noise level. It's great for keeping tabs on what's going on in rooms in your house, office, or elsewhere. Push the data to server and you can view the data remotely from anywhere.

Compatible with:

€39.95

News

Drumroll, please! We're delighted to reveal the lucky winner of the Promarker Mixed Marker Set of 24 🎉🏆🎉

2024 is here, and the competition is on! Win an Amazing Promarker Set now!

16 Nov 2023

Flux Ador Unleashes the Future of Creative Laser Cutting: The World's First Colour Printing Laser Cutter

Flux Ador, the innovative colour printing laser cutter, takes creativity to new heights with precise, vibrant designs while also engraving a wide range of materials, including metal, opening up endless creative possibilities.

Great Offers!

Chatter is a free, private, security-first texting device. It comes in a pair because texting yourself is not as fun as you think.

Unlike your regular phone, this device does not need a cellular network or a SIM card to work because it creates its own wireless network and communicates with other Chatter devices you've paired it with.

It uses the so-called “LoRa; low-power wide-area network technology in order to send text messages, emojis, memes, and GIFs. Chatter uses a publicly-available set of frequencies that are allocated for use cases like this one.

Hardware skills:Soldering & hardware assembly

Wireless communication systems and LoRa

Electronic components

Coding skills:Coding in C++ & CircuitBlocks

Low power & always-on technology

Embedded programming

Video game mechanics

Unlike your regular phone, this device does not need a cellular network or a SIM card to work because it creates its own wireless network and communicates with other Chatter devices you've paired it with.

It uses the so-called “LoRa; low-power wide-area network technology in order to send text messages, emojis, memes, and GIFs. Chatter uses a publicly-available set of frequencies that are allocated for use cases like this one.

Hardware skills:

Coding skills:

€179.95

€149.95

Go To Product Page

Learn how to solder and get a fully functional retro gaming console with the Nibble, the new and improved version of MAKERbuino. This amazing kit teaches you all about electronics from soldering to coding and contains everything that you need in order to build your own gaming console along with a full assembly guide making it perfect for makers of all levels.

Nibble is based on ESP8266 - a microcontroller used on various Arduino development boards. Therefore, it can be programmed in the Arduino IDE (based on C/C++) - the most popular programming environment for makers. Nibble comes preloaded with four retro games inspired by cult classics

Nibble is based on ESP8266 - a microcontroller used on various Arduino development boards. Therefore, it can be programmed in the Arduino IDE (based on C/C++) - the most popular programming environment for makers. Nibble comes preloaded with four retro games inspired by cult classics

€112.95

€89.95

Go To Product Page

All the Field Elements & Game Objects needed to build a complete 2021-2022 VEX IQ Challenge field. One Full Field Set.

Note: VEX IQ Challenge Field Perimeter & Tiles are not included with this Kit. Must be added separately.

Note: VEX IQ Challenge Field Perimeter & Tiles are not included with this Kit. Must be added separately.

€159.90

€99.00

Go To Product Page

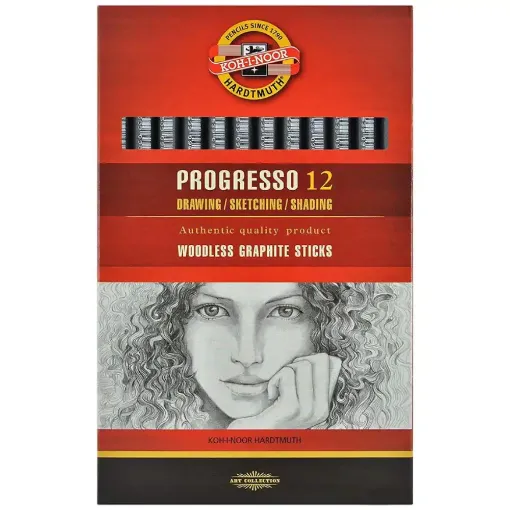

Graphite lacquered pencil with strong mark.

Perfect for artists, hobby and school drawing.

Perfect for artists, hobby and school drawing.

€9.26

€7.95

Go To Product Page